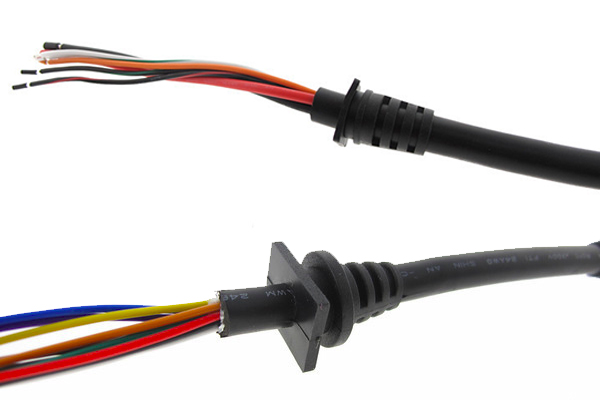

Overmolding Design Considerations When designing cable assemblies engineers are using the overmolding process to provide strain or bend relief. This includes grommets as part of the assembly for any points where an assembly needs to be installed through a housingopening and as a covering for the connector backshells to protect the termination points and contacts.

Overmolding Ultimate Guide Best Molding Companies In The Usa

Check out this page for more on overmolding materials and processes.

. Table of Contents Introduction 1. Overmolding a cable connector typically employs a two-step process step 1 apply the inner mold the first step is to apply an. Apply the Inner Mold The first step is to apply an inner mold which is used to encapsulate the terminations and the cable wires as well as provide a support structure for the exterior or cosmetic outer mold.

Cable Overmolding Design Guide - manufacturer factory supplier from China Total 24 Products for Cable Overmolding Design Guide Cigarette Cable For Charging. Cable Overmolding Design Guide. Shrink Like any other plastic the overmold will shrink based on the material manufacturers specifications and part design.

Cable or wire assemblies are placed within a mold which is then injected with a pressurized molten plastic. Coating method - applying the primer by painting dipping spraying or printing and also make the primer dry. After the substrate has cooled the mold opens and the B-Plate movable side of the mold rotates 180 without ejection of the substrate.

Different substrate need different primer. Elimination of Fasteners and Adhesive. Since more shrink is present with larger wall thicknesses its important to make sure that the overmold does not shrink away from the substrate.

Overmolded cable assemblies go a step beyond a simple sheath by enclosing the cable or wire and connector with overmolded material. Once the material hardens it turns into a protective layer that seals the junction between the wires. Custom waterproofing M8 sensor cable splitter Y type.

We are searching ahead towards your visit for joint growth for cable overmolding design guide S102z056-130 Epg Fixed Socket Plastic Front NutFgg Connector. Table of Contents Introduction 1. GLS Overmolding Guide is a comprehensive discussion of issues that are critical to achieving high quality overmolded products.

Cable OvermoldingMilitary Market Applications. Once the required temperature has been achieved the mould opens and an array of pins sleeves strippers etc. With many important considerations to make for a successful cable assembly overmolding can make or break your product.

If the part requires the use of thick sections they should be cored out to minimize shrinkage problems and to reduce the part weight. Overmolding Guide is a comprehensive discussion of issues that are critical to achieving high quality overmolded pr oducts. Wall thickness in the range from 0060 to 0120 will ensure good bonding in most overmolding applications.

Design for a nominal 0063 thickness of chem 860 over the flat surfaces. Cable overmolding design guide - Factory Suppliers Manufacturers from China. It can be our accountability to satisfy your preferences and competently provide you.

Although this process is cost-effective and helps to provide excellent adhesion between materials it requires proper planning. The high usefulness of over-molded cables makes them very efficient and durable and in sync with the latest technology. Cable Overmolding Design Guide - manufacturer factory supplier from China.

Overmolding is an injection molding process where you cast a layer of resin usually a rubber-like plastic known as TPE over an already molded or machined material to give it properties it doesnt singlehandedly possess. Military components now use over-molding for longevity and more effectiveness and durability. Typically molded circular connectors have an internal premold which is the part of a molded connector body that is not seen but is nonetheless integral to the part structure.

Custom truck diagnostic J1962 OBD2 coverter cable with APEX 28MM connector. Silicone overmolding - put silicone rubber material into mold cavity with metalglass substrate together and molding. Cable Assemblies For EV Battery System.

This guide is a compilation of over thirteen years of experience in the developmentdesign and processing of overmolding TPEsbased on contributions from a variety of GLS and industry sources. This helps to protect electrical components from dust dirt and debris. Minnesota wire custom designs develops and manufactures wire cable and.

NUMBERWe reserve the right to. The applications of over-molded cables are as follows. SAE black J1939M to J1939P cable assemblies.

Customized 7pin flat trailer connector cable assemblies. Our free Overmolding Guide offers everything you should know including. Our basic guidelines for overmolding and insert molding include important design considerations to help improve part manufacturability enhance cosmetic appearance and reduce overall production time.

If the overmold is only on one side of the part the two B-side cavities are identical. Overmolding a cable connector typically employs a two-step process. The process of overmolding helps to create a material bond around wirecables PCBs and connectors that provide watertight seals.

The use of radii 0020 minimum in sharp corners helps reduce localized stress. Size Maximum Dimensions IN MM Height may be limited if using a silicone as the overmold material and deeper parts are limited to a smaller outline. Barrel A fills the substrate set of cavities.

The guide will make cable overmolding design guide. The two shot molding process includes the following steps. The Applications of Cable Overmolding.

This guide is a compilation of more than 25 years of experience in the de velopment design and processing of over molding TPEs based on contributions from a variety of Avient and industry sources. As a result the overmolded electrical assembly can achieve IP67 IP68 and IP69K standards. Your satisfaction is our greatest reward.

Material Selection Molding Design Technologies Used for Overmolding Prototypes Download the Guide CONTACTING iCONN. Molded Audio Cable Assemblies.

Overmolded Cable Assemblies Customization Conwire

Overmolded Cable Connectors The Minimally Invasive Guide

Everything To Know About Custom Overmolded Cable Assemblies

Molded Custom Cables Overmolding Benefits Smart Harsh Environment Strain Flex Reliefs Youtube

Everything To Know About Custom Overmolded Cable Assemblies

Everything To Know About Custom Overmolded Cable Assemblies

Managing The Development Of Your Overmolded Cable Youtube

Incorporating Pcbs And Leds Into An Outdoor Overmolded Cable Design

0 komentar

Posting Komentar